Thermal Gap Pads Market Projected to Surpass $2.5 Billion by 2025: Insights from the U.S., Japan, and China

Explore the dynamic Thermal Gap Pads market, including industry chain analysis, raw materials, manufacturing processes, supply chain insights, trends shaping the market in 2025, key industries driving growth, challenges in production and sourcing, applications across electronics, automotive, and consumer goods, regional demand insights, and future advancements. Anticipate a market value surpassing $2.5 billion by 2025.

- Last Updated:

Thermal Gap Pads Market in Q1 and Q2 of 2025

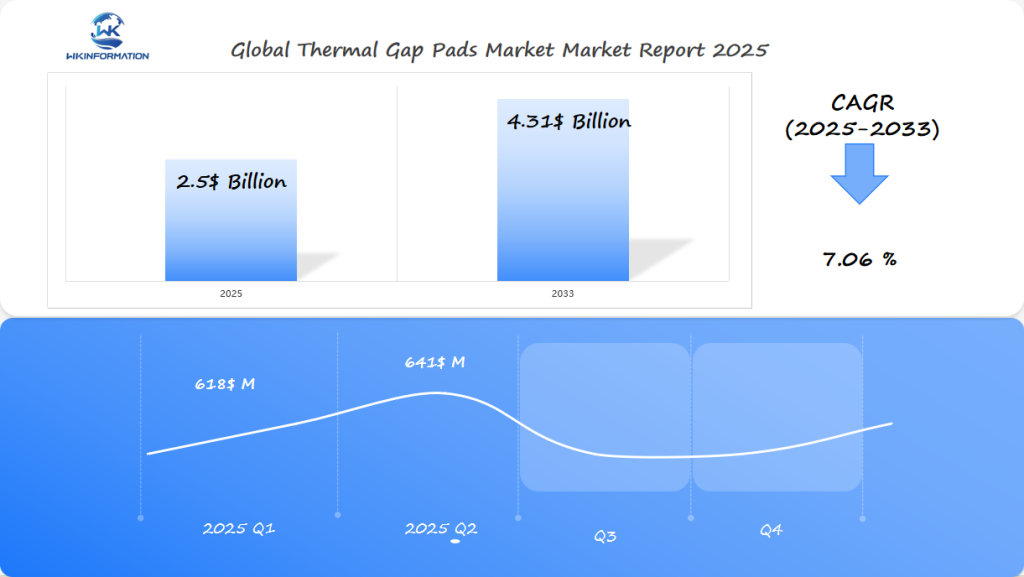

The Thermal Gap Pads market is projected to reach $2.5 billion in 2025, growing steadily at a CAGR of 7.06% from 2025 to 2033. In Q1 2025, the market is estimated to generate around $618 million, with Q2 expected to follow closely at $641 million, driven by robust demand for thermal interface materials across high-performance electronics and EV powertrains.

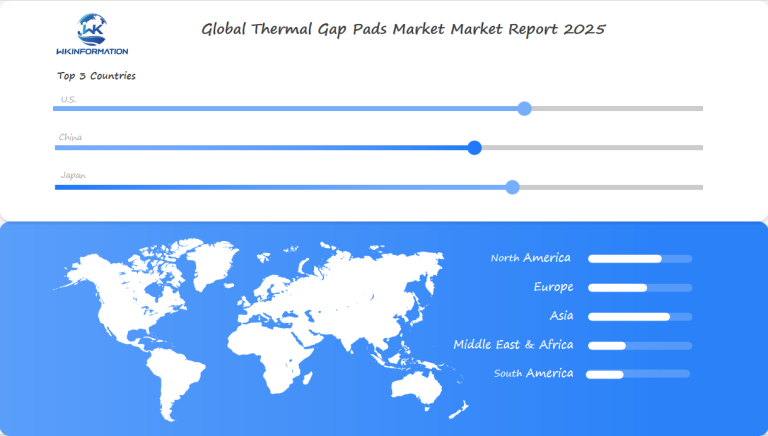

In the U.S., growth is fueled by the rapid expansion of electric vehicle (EV) manufacturing and data centers requiring advanced thermal management. Japan continues to lead in miniaturized consumer electronics and LED applications that demand efficient heat dissipation. Meanwhile, China is witnessing accelerated investment in 5G infrastructure and battery modules, contributing to rising adoption of thermal gap fillers. The first half of 2025 is showing strong procurement trends across OEMs and EMS providers.

Key Takeaways

- Projected market value of $2.5 billion by 2025

- Significant growth in thermal interface materials sector

- Critical importance in electronics and technology industries

- U.S., Japan, and China emerging as market leaders

- Increasing demand for advanced heat management solutions

Thermal Gap Pads market upstream and downstream industry chain analysis

The thermal gap pads industry is a complex web of processes. It turns raw materials into essential thermal management solutions. Manufacturers face many challenges in sourcing and production.

Raw Materials: The Building Blocks of Thermal Gap Pads

Raw materials are key to the quality and performance of thermal gap pads. The main components are:

- Silicone polymers

- Ceramic fillers like alumina

- Boron nitride

- Specialty thermal conductive materials

Manufacturing Process: Transforming Raw Materials into Thermal Gap Pads

Material costs are a big part of the manufacturing process. They make up 40-55% of the total costs. Fluctuations in raw material prices make it hard for manufacturers to keep quality and prices stable.

The manufacturing process needs precise engineering for the best thermal conductivity. Advanced methods mix, compress, and cure materials to make top-notch thermal interface materials.

Supply Chain: Connecting Upstream and Downstream Players

Strategic sourcing and efficient supply chain management are key in the thermal gap pads market. Here’s how the supply chain looks:

| Upstream Suppliers | Raw material providers specializing in thermal conductive compounds |

| Manufacturers | Specialized facilities converting raw materials into thermal gap pads |

| Downstream Distributors | Electronics, automotive, and consumer goods sectors |

Manufacturers must keep innovating to meet new technology demands and stay ahead.

Trends Shaping the Thermal Gap Pads Market in 2025

The thermal gap pads market is changing fast. This is thanks to new tech and more uses in different fields. Electronics makers want devices that work better, leading to a big need for better heat management.

Many areas are seeing big changes, especially in electronics and mechanical systems. The need for smaller, more powerful devices is making thermal gap pads better.

Key Industries Driving Growth

- Consumer electronics

- Electric vehicles

- Telecommunications

- Renewable energy

Specific Applications Within Each Industry

- Smartphone cooling in consumer electronics

- Battery thermal management in automotive

- 5G infrastructure cooling in telecommunications

- Solar inverter cooling in renewable energy

Growth Potential in Each Application

| Industry Sector | Thermal Gap Pad Application | Growth Potential |

| Consumer Electronics | Smartphone Cooling | High |

| Automotive | Battery Thermal Management | Very High |

| Telecommunications | 5G Infrastructure Cooling | Moderate |

| Renewable Energy | Solar Inverter Cooling | High |

The market is expected to grow a lot. Electronics and electrical making will use over 40% of thermal gap pads by 2025. New materials and designs will keep this market exciting.

Innovations in Thermal Gap Pads

New tech is making thermal gap pads more advanced. Companies are making materials that conduct heat better and are more flexible. This helps solve heat problems in many industries.

The demand for efficient heat dissipation solutions across various sectors is driving the growth of the thermal gap pads market. As industries continue to evolve and embrace new technologies, the need for effective thermal management solutions will remain crucial for optimal performance and reliability.

Challenges in the Production and Sourcing of Thermal Gap Pads

The thermal gap pads industry faces big challenges in making these products. Making them requires a lot of energy, which makes things hard for manufacturers. They need to keep prices low and quality high.

Finding the Right Materials

Finding the right materials is a big problem. Companies have to find and buy special materials that work well. But these materials are hard to find, which makes costs go up and can cause delays.

- High-temperature curing requirements increase manufacturing expenses

- Advanced thermal management systems add significant per-kilogram production costs

- Specialized material sourcing creates supply chain vulnerabilities

Keeping Quality High

Keeping quality high is another big challenge. Companies have to test their products a lot to make sure they work well. Even tiny differences in materials can affect how well they transfer heat.

Solutions Through Technology

Companies are using new technologies to solve these problems. They’re using machines to make things faster and better. They’re also getting better at finding and checking materials. And they’re using new ways to make sure their products are top-notch.

Geopolitical Impact on Thermal Gap Pads Manufacturing and Trade

The world of thermal gap pads manufacturing is changing fast. This is due to complex global politics. International trade is getting more complicated, with big changes in key places.

Several important factors are changing how thermal gap pads are made and traded:

- Shifting production strategies in Southeast Asian markets

- Emerging tariff structures affecting material sourcing

- Regional trade policy negotiations

- Technological transfer restrictions

Companies are coming up with smart plans to deal with tough international trade situations. Cost optimization is a big goal. They are looking for new places to make things to avoid high tariffs.

Recent data shows interesting facts about where things are made. Southeast Asian makers are getting better, saving about 22% on delivery costs. This is compared to old European suppliers for Chinese electric cars.

The United States is still very important in global trade. Tariffs on things like silicone rubber from China are making companies rethink their plans. They are building stronger supply chains.

Being able to innovate and adapt will help companies deal with these big challenges in the thermal gap pads market.

Type Segmentation: Silicone vs. Non-Silicone Thermal Gap Pads

The thermal gap pad market is growing fast. New materials are being made to solve heat problems in many fields. These new solutions help improve how well they work and where they can be used.

Thermal interface materials are key for cooling down complex electronics and machines. Engineers need to pick the right materials. They look for the best heat transfer and fit with the system.

Silicone-Based Thermal Gap Pads

Silicone-based thermal gap pads have great features for cooling:

- High thermal conductivity ranging from 1-6 W/mK

- Excellent compressibility and conformability

- Superior temperature stability (-55°C to 200°C)

- Biocompatible and chemically inert

Non-Silicone Thermal Gap Pad Alternatives

Non-silicone materials have special traits for certain uses:

- Ceramic-filled polymer compounds

- Graphite-based thermal interfaces

- Synthetic rubber alternatives

Choosing the right thermal gap pad depends on what you need. This includes how well it conducts heat, how it handles stress, and the environment it’s in.

Applications for Thermal Gap Pads in Electronics, Automotive, and Consumer Goods

Thermal gap pads have transformed how we manage heat in various industries. They address significant challenges by adapting to specific requirements. These materials are crucial for maintaining optimal temperatures and ensuring proper functionality.

These pads are highly versatile as they can tackle complex heat problems. They establish a connection between hot components and cooler areas, making them indispensable in today’s technological landscape.

Electronics Industry Applications

In electronics, thermal gap pads do a lot:

- They cut down heat between parts

- They make heat move better in tight spaces

- They make semiconductors more reliable

Automotive Sector Usage

Car makers use thermal gap pads for better battery control. With electric cars on the rise, this tech is getting more important.

| Automotive Application | Thermal Management Purpose |

| Battery Modules | Temperature Regulation |

| Power Electronics | Heat Dissipation |

| Electric Drivetrain | Performance Optimization |

Consumer Goods Integration

Thermal gap pads also help gadgets last longer. Smartphones, laptops, and gaming devices use them to stay cool and work better.

Global Market Insights: Regional Demand for Thermal Gap Pads

The global thermal gap pads market is complex. It’s shaped by new technologies and industrial growth. Different areas grow at different rates, showing how demand for thermal solutions varies.

Some areas are growing faster than others. Key places include:

- North America: Known for its tech

- Asia-Pacific: Growing fast

- Europe: High manufacturing standards

- Middle East: New tech coming in

New markets are quickly taking up thermal gap pad tech. This is true in electronics and cars. Advances in tech and more complex products are why.

The market has its own traits:

- High-tech electronics need good cooling

- Cars need smart cooling systems

- Consumer electronics use thermal gap pads too

Investments in research help shape the market. Companies are working on better materials. These materials should work well and not cost too much.

U.S. Market Analysis: Growth in Thermal Gap Pads for Electronics and Automotive Sectors

The North American market for thermal gap pads is a key area for innovation in thermal management. The United States leads in advanced thermal interface materials, thanks to its strong electronics and automotive sectors.

Industry leaders are constantly improving thermal gap pads through research and development. New technologies are changing how these pads are made and used in different areas.

Factors Driving Growth

- Electronics sector driving demand: The electronics industry is pushing for high-performance thermal management solutions to keep devices cool and efficient.

- Automotive manufacturers seeking solutions: Car manufacturers are looking for better ways to dissipate heat from engines and electric vehicles.

- Regulatory compliance shaping development: Strict regulations are influencing the design and materials used in thermal gap pads.

Importance of Regulatory Standards

Regulatory standards play a crucial role in the market. Underwriters Laboratories (UL) certifications are essential for manufacturers of thermal gap pads. These certifications ensure that products meet high standards of performance and safety.

The Silicon Valley area is a hub for new thermal gap pad technologies. Startups and large companies are collaborating to tackle complex thermal management challenges with innovative solutions.

Japan's Leadership in Thermal Gap Pad Innovation and Production

Japan leads in thermal gap pad technology, showing great leadership in research and development in Asia. The country’s focus on making things better has made it a key player in thermal management for electronics and cars.

Japanese makers have created new technologies in thermal interface materials, especially in silicone gap pads. Their detailed market research has led to big improvements in how well these materials work.

- Developed specialized JIS K 6249 standards for automotive thermal interface materials

- Achieved 18% annual growth in silicone rubber applications for electric vehicle power electronics

- Established global benchmarks in thermal management technology

Top Japanese companies have put a lot of effort into making thermal gap pads that can handle heat well. Their new ideas have changed how we manage heat in many high-tech fields, from gadgets to car systems.

Japan keeps pushing the limits of thermal management technology. This has made it a top name in Asia for advanced materials engineering.

China's Expanding Market for Thermal Gap Pads in Electronics Manufacturing

China has become a major player in making thermal gap pads for electronics. It’s a key spot for growth in the global electronics world. The country’s strong manufacturing setup makes it a leader in keeping electronics cool.

China’s Role in the Thermal Gap Pad Market

China’s role in the thermal gap pad market is huge. Its makers are getting better at making top-notch materials for cooling electronics. These materials are needed more and more as electronics get more complex.

- Dominates global silicone resin production

- Offers competitive pricing strategies

- Invests heavily in research and development

Boosting the Market with Semiconductors and Electronics

China’s push into semiconductors and electronics has boosted its thermal gap pad market. Local companies are coming up with new, advanced cooling solutions. These solutions are as good as those from other countries.

Some big tech steps include:

- Materials that conduct heat better

- Stuff that lasts longer in tough places

- Custom solutions for different uses

The Chinese thermal gap pad market is set to grow a lot. This is because of more electronics being made and a need for better cooling tech.

Future Outlook: Advances in Thermal Gap Pad Technologies

The thermal gap pad market is undergoing a significant transformation due to the introduction of new products and technologies. Researchers are actively engaged in developing improved thermal interface solutions, with the goal of addressing complex heat management challenges.

New Trends in Thermal Management

Recent developments indicate that various factors are reshaping the landscape of thermal management. Here are some key areas where researchers are focusing their efforts to enhance the performance of these materials:

- Nano-enhanced materials: These materials incorporate nanoscale additives to enhance their thermal conductivity properties, enabling them to dissipate heat more effectively.

- Hybrid materials: By combining different types of fillers such as advanced ceramics with traditional polymer matrices, hybrid materials aim to achieve superior thermal performance compared to conventional options.

- Smart materials: Incorporating built-in sensors or actuators into thermal interface materials allows for real-time monitoring and adjustment of heat dissipation, optimizing overall system performance.

The Growing Demand for Ultra-High Thermal Conductivity Materials

There is an increasing demand for materials that can provide exceptionally high thermal conductivity. Scientists are actively researching ways to develop gap pads capable of achieving thermal conductivity values up to 12 W/m·K by exploring innovative combinations of silicone rubber, boron nitride, and alumina fillers.

The Impact of Emerging Technologies on Thermal Management

The rise of technologies such as artificial intelligence (AI) and fifth-generation wireless (5G) communication is amplifying the significance of effective thermal management solutions. This is particularly evident in industries such as consumer electronics and automotive, where compact designs and powerful components necessitate efficient heat dissipation strategies.

To meet these evolving cooling requirements, companies are investing heavily in advanced thermal gap pad technologies. These investments aim to develop next-generation materials capable of accommodating higher power densities while maintaining reliability under demanding operating conditions.

The Vision for Future Thermal Gap Pads

Experts predict that the future of thermal gap pads lies in the development of intelligent and adaptable materials. These innovative solutions will revolutionize how we manage heat within electronic devices, enabling greater design flexibility and improved performance.

Anticipated Advancements Over the Next Decade

Looking ahead, it is expected that significant advancements will occur within the field of thermal gap pad technology over the next ten years. Key trends anticipated during this period include:

- Increased integration of sustainability practices: As environmental concerns continue to rise globally, there will be a growing emphasis on developing eco-friendly manufacturing processes and utilizing recyclable or bio-based raw materials in production.

- Enhanced customization capabilities: With the advent of additive manufacturing techniques such as 3D printing, it will become possible to create bespoke thermal interface solutions tailored specifically for unique applications or product designs.

- Expanded collaboration between industries: Cross-sector partnerships between electronics manufacturers, automotive companies, and material suppliers can foster knowledge exchange leading towards innovative approaches towards tackling common challenges faced across multiple domains.

These anticipated developments hold immense potential not only for enhancing existing applications but also opening doors towards entirely new possibilities within high-tech sectors including consumer electronics and electric vehicles.

Competitive Landscape: Major Players in the Thermal Gap Pads Market

Key Players:

- Bergquist — USA

- Laird Performance Materials — USA

- Advanced Thermal Solutions (ATS) — USA

- Würth Elektronik — Germany

- TE Connectivity — Switzerland

- Vicor — USA

- MG Chemicals — Canada

- Lantronix — USA

- Boyd Corporation — USA

- Sheen Technology — China

Each company has its own way of making thermal gap pads. Strategic partnerships and ongoing research are key to success. Companies are investing in new thermal technologies to meet the needs of electronics and cars.

The market is always getting better with new technologies. Companies like Honeywell International and Semikron are leading the way in thermal solutions. They are not just competing; they are working together to improve the market.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Thermal Gap Pads Market Report |

| Base Year | 2024 |

| Segment by Type |

· Silicone-Based Thermal Gap Pads · Non-Silicone Thermal Gap Pads |

| Segment by Application |

· Electronics Industry · Automotive · Consumer Goods · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The thermal gap pads market is full of opportunities for smart investors. The forecast shows a big growth, with the electronic thermal interface materials market set to grow from USD 2.5 Billion in 2025 to USD 4.31 Billion by 2033. This growth means big chances for investment in many fields, especially in electronics and cars.

Investors should look at new tech like materials that conduct heat better. There’s a big chance in areas like super-fast computers, electric cars, and green energy. Investing in new gap pad tech could bring big rewards.

But, it’s important to watch out for risks in this fast-changing market. To succeed, you need to understand new tech, how things are made, and different markets. Companies that stay ahead with new thermal management tech will see more demand.

Global Thermal Gap Pads Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Thermal Gap Pads Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Thermal Gap Pads Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Thermal Gap Pads Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Thermal Gap Pads Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Thermal Gap Pads Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Thermal Gap Pads Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Thermal Gap Pads Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are thermal gap pads and why are they important?

Thermal gap pads are special materials that help transfer heat between electronic parts and heat sinks. They are key in many fields like electronics, cars, and home goods. They help keep things cool and work better by getting rid of heat.

How large is the thermal gap pads market expected to grow?

The market for thermal gap pads is set to grow big, reaching over $2.5 billion by 2025. This growth is thanks to more use in gadgets, cars, 5G tech, and green energy.

Which industries primarily use thermal gap pads?

Industries such as electronics, automotive, consumer electronics, telecommunications, and renewable energy heavily rely on thermal gap pads. These industries utilize thermal gap pads for effective heat management, ensuring optimal performance and reliability of their devices.

What are the main types of thermal gap pads?

There are mainly two types: silicone-based and non-silicone thermal gap pads. Each has special features like how well they conduct heat, how they handle pressure, and how stable they are. This makes them good for different uses and places.

What challenges do manufacturers face in producing thermal gap pads?

Making thermal gap pads is hard because:

- It uses a lot of energy

- Materials can be hard to find

- Quality must be high

- New ideas are always needed

These challenges keep the industry busy and competitive.

How do geopolitical factors impact the thermal gap pads market?

Factors such as trade regulations, tariffs, and international relationships influence production locations, distribution methods, and sales channels. To remain competitive, companies must stay informed about these developments.

Which regions are leading in thermal gap pads innovation?

The U.S., Japan, and China are leading in making thermal gap pads better. The U.S. is great at new tech, Japan makes high-quality stuff, and China is big in making lots and meeting new market needs.

What future technologies might impact thermal gap pads?

New tech like nano-materials, AI, 5G, and advanced materials will change thermal gap pads a lot. They will make these pads work better and do more.

How do thermal gap pads contribute to electric vehicle technology?

Thermal gap pads are essential in electric vehicles for maintaining the temperature of batteries and electronics. By effectively dissipating heat, these pads ensure optimal performance and safety of the car’s components.

What factors drive the growing demand for thermal gap pads?

The increasing demand for thermal gap pads is attributed to several factors. These include the trend towards smaller devices, higher power consumption, the necessity for improved cooling solutions, advancements in electronic technology, and a surge in usage within rapidly expanding sectors such as smartphones and automotive industries.