Cleanroom Paper Market to Surpass $3.74 Billion by 2025: Insights into Trends in the U.S., Japan, and South Korea

Discover key trends driving the Cleanroom Paper Market growth, including demand surge in semiconductor manufacturing, healthcare, and biotechnology sectors across US & global regions.

- Last Updated:

Cleanroom Paper Market Q1 and Q2 of 2025

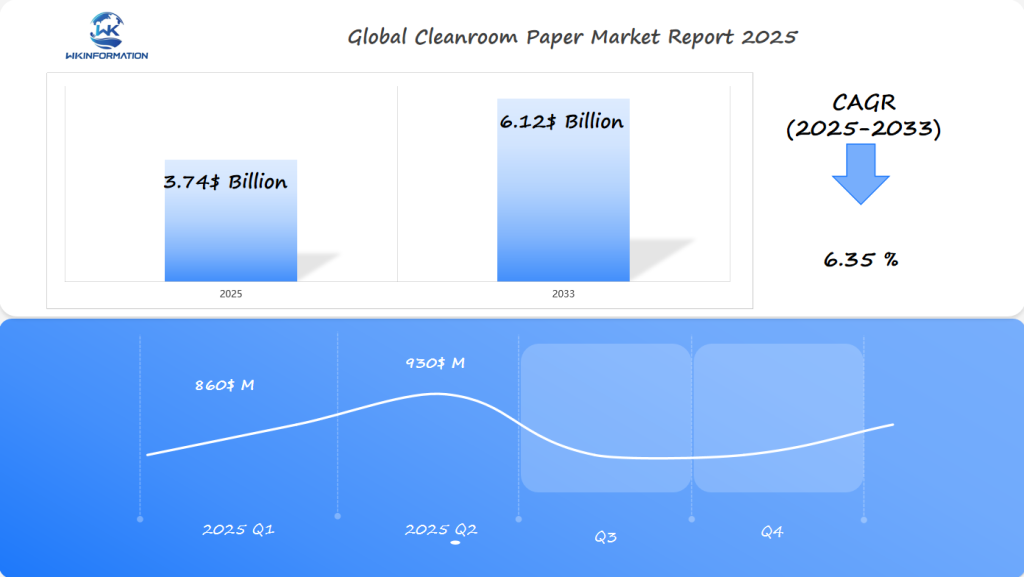

The cleanroom paper market is projected to hit $3.74 billion by 2025, with a CAGR of 6.35% through 2033. Q1 market valuation stands at about $860 million, growing to approximately $930 million in Q2. Widely used for documentation, printing, and packaging in controlled environments, cleanroom paper is essential in the semiconductor, biotech, and pharmaceutical sectors.

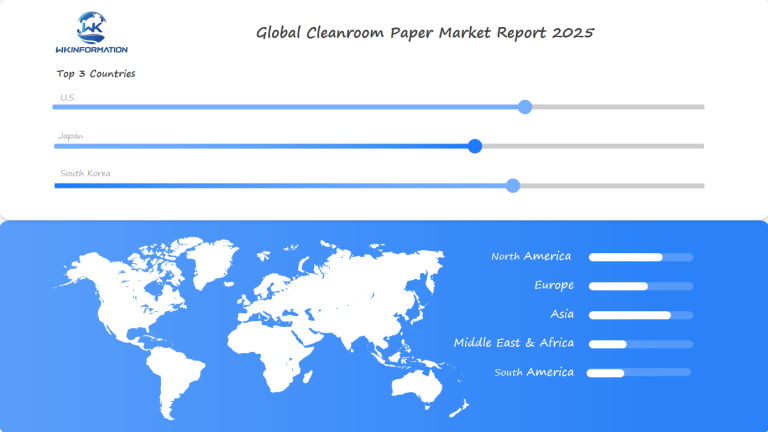

The U.S. continues to lead due to manufacturing expansion under chip and clean energy incentives. Japan’s strict manufacturing protocols and R&D practices support steady market growth, while South Korea’s demand rises in tandem with the expansion of OLED and semiconductor fabrication facilities. Upstream demand for synthetic fiber blends and particle-free pulp materials remains strong, feeding a downstream market of cleanroom printers, notebooks, and documentation systems.

Upstream and Downstream Analysis of the Cleanroom Paper Market

Raw Material Sourcing and Pre-Processing Considerations

The upstream segment of the Cleanroom Paper market involves the procurement and refinement of ultra-clean base materials. High-grade cellulose fibers, synthetic polymers such as polyester or polypropylene, and specialty chemical additives are sourced from certified vendors capable of meeting stringent contamination control requirements. These inputs undergo pre-processing techniques including chemical purification, anti-static treatment, and fiber surface modification to ensure compatibility with cleanroom environments ranging from ISO Class 3 to Class 7.

Precision Manufacturing Within Controlled Environments

The core manufacturing phase is marked by tightly regulated production protocols. Cleanroom paper is fabricated using particle-free equipment and deionized water systems to ensure minimal ionic contamination and low particulate generation. Processes such as multi-stage calendaring, surface sealing, and non-contaminating slitting are critical for achieving dimensional stability, printability, and cleanliness. Packaging is done in sealed, cleanroom-grade containers to preserve product integrity during logistics.

Targeted Distribution and Industry-Specific End-Use

Downstream activities include tailored distribution strategies targeting sectors such as microelectronics, biopharma, aerospace, and medical device production. Cleanroom paper is used for operational logging, batch documentation, labeling, and instructions for use (IFUs) where particle control is essential. Growth in these industries, coupled with increased regulatory scrutiny, is expanding the customer base. Products must conform to standards such as RoHS, REACH, and ISO 14644, with end-users demanding compatibility with both laser and inkjet printing systems.

Strategic Market Outlook

The Cleanroom Paper market thrives on the synergy between upstream purity and downstream reliability. As clean manufacturing practices become more widespread globally, suppliers who optimize both material science and distribution efficiency will be best positioned to capture emerging opportunities.

Major Trends Shaping the Cleanroom Paper Industry

The cleanroom paper industry is changing fast. New technologies and market needs are leading the way. Companies are working hard to create better solutions for keeping things clean in many fields.

1. Technological Advancements

Big changes are happening in the cleanroom paper market. New tech has made paper products better. They can handle more and are cleaner:

- Ultra-low particle generation materials

- Improved chemical resistance

- Enhanced moisture absorption capabilities

- Specialized surface treatments

2. Market Demand

Market needs are pushing cleanroom paper to new heights. Industries like making semiconductors, drugs, and medical devices need better ways to control contamination.

| Industry Sector | Cleanroom Paper Demand | Key Requirements |

| Electronics | High | Minimal particle shedding |

| Pharmaceutical | Medium-High | Sterility preservation |

| Medical Devices | High | Contamination prevention |

3. Investment in Research and Development

New tech is making cleanroom paper better. Companies are spending on research. They’re making nano-engineered materials for top-notch performance in tough places.

The future of cleanroom paper lies in precision engineering and advanced material science.

These trends show cleanroom paper is on the rise. It’s in demand by high-tech and precise manufacturing. This means more innovation and new products.

Key Market Restrictions and Challenges Affecting Cleanroom Paper Growth

The cleanroom paper industry faces big challenges that slow its growth. Strict rules make it hard for companies to grow. They need to follow many rules and check their quality closely.

There are many reasons why growth is hard:

- High production costs limit market growth

- Special technology is needed for making cleanroom paper

- Very strict rules for keeping things clean in sensitive areas

- Not enough top-quality materials for making cleanroom paper

Companies have to make paper that meets high standards without spending too much. The need for such precision makes it hard for new companies to enter the market.

“Overcoming these market challenges requires innovative manufacturing approaches and strategic investment in advanced technologies.” – Industry Expert

Pharmaceutical, semiconductor, and medical device industries have the toughest standards for cleanroom paper. They need paper that filters out almost all particles and keeps things clean. This makes making the paper more complex and expensive.

Companies need skilled people and a lot of money to overcome these challenges. They must keep up with changing rules and still offer good prices.

Geopolitical Considerations Impacting the Cleanroom Paper Market

The cleanroom paper market is influenced by various global factors, including trade policies and international relations. These factors create both challenges and opportunities for manufacturers and suppliers of cleanroom paper.

Key Factors Influencing the Market

Some of the key factors that impact the cleanroom paper market include:

- Changes in trade agreements between major countries

- Economic sanctions affecting the supply of raw materials

- Technological advancements in cleanroom paper production across different regions

- Collaborations between companies from various nations

Understanding Global Market Trends

Global market trends provide insights into how markets expand or contract. Emerging countries are adopting advanced cleanroom paper technology, posing challenges to established leaders. Being tech-savvy and strategic is crucial for staying competitive.

Managing Complex Global Relationships

To maintain robust supply chains, companies must navigate intricate global connections. The U.S., Japan, and South Korea are significant players in the cleanroom paper market. Understanding the global landscape enables businesses to remain resilient and adaptable.

Being flexible and adaptable is crucial for success in the global cleanroom paper market.

The Impact of Trade Policies

Trade policies are constantly evolving, presenting both obstacles and opportunities for global cleanroom paper manufacturers. Companies that comprehend and respond to these changes will prosper in the dynamic market.

Analyzing Different Types of Cleanroom Paper Products Available in the Market

The cleanroom paper market has a wide range of products. These are made to meet strict industrial needs. Product analysis shows many types of cleanroom paper for different settings.

1. Low-Particle Paper

Low-Particle Paper is specifically designed for areas that require an extremely clean environment with minimal risk of contamination. This type of paper is manufactured using advanced techniques to ensure that it generates very few particles and does not introduce any contaminants into the cleanroom.

2. Synthetic Substrate Papers

Synthetic Substrate Papers are specially engineered for industries such as electronics and semiconductor manufacturing, where cleanliness is critical. These papers are made from synthetic materials that offer excellent resistance to tearing, moisture, and chemicals, making them suitable for use in demanding cleanroom applications.

3. Cellulose-Based Cleanroom Papers

Cellulose-Based Cleanroom Papers are commonly used in pharmaceutical and medical research facilities. These papers are made from natural cellulose fibers and provide good absorbency properties, making them ideal for tasks such as wiping surfaces or handling sensitive equipment.

4. Microfiber Cleanroom Wipes

Microfiber Cleanroom Wipes are specifically designed for detailed cleaning tasks in cleanrooms. These wipes are made from ultra-fine microfiber materials that can effectively trap dust, dirt, and other particles without leaving any residue behind.

Market segmentation shows that various industries need specific paper types. Manufacturers aim to create products with certain features. These include:

- Ability to hold particles

- How well it absorbs

- Resistance to chemicals

- Strength

Research shows that new technology keeps improving cleanroom paper. New materials and ways of making it lead to better products. These products meet the changing needs of industries.

Exploring the Applications of Cleanroom Paper Across Various Industries

Cleanroom paper is key in keeping contamination under control in many precise industries. These papers are made to be super clean. They are vital in places where tiny particles can ruin product quality.

Key Areas Using Cleanroom Paper

Cleanroom paper is used in many important areas:

- Pharmaceutical Manufacturing

- Semiconductor Electronics

- Biotechnology Research

- Aerospace Engineering

- Medical Device Production

Pharmaceutical Manufacturing

In drug making, cleanroom paper is used to keep things sterile. The need for papers that don’t shed particles is growing. This is because rules for cleanliness are getting stricter.

| Industry | Primary Cleanroom Paper Use | Contamination Sensitivity |

| Semiconductor | Surface Cleaning | Extremely High |

| Biotechnology | Lab Wiping | High |

| Medical Devices | Sterile Environments | Critical |

Semiconductor Electronics

For electronics makers, cleanroom paper is a must. It’s great at keeping particles away. Precision is key in making semiconductors. A single tiny particle can mess up a whole chip.

“Cleanroom paper is not just a product, it’s a critical technology enabling innovation across high-performance industries.” – Industry Expert

Biotechnology Research and Medical Devices

In the fields of biotechnology research and medical device production, the use of cleanroom paper ensures that sensitive processes and environments remain uncontaminated.

The Growing Demand for Advanced Cleanroom Paper

The need for better cleanroom paper is growing. This shows how complex making things has become. As tech gets more advanced, so does the need for clean materials.

Global Regional Overview of the Cleanroom Paper Market Landscape

The global cleanroom paper market is complex and changing fast. Different regions are seeing big changes in who’s leading the market. This is because of new tech and specific needs in each area.

Looking at the cleanroom paper market, we see some important trends:

- North America is at the forefront with the latest cleanroom paper tech.

- Asia-Pacific is growing fast in the market.

- European markets are focusing on making things more sustainable.

What’s really shaping the global market includes:

- More making of semiconductors and electronics.

- Tighter rules for keeping things clean.

- More research in pharmaceuticals and biotechnology.

The way market share is spread out shows interesting patterns:

| Region | Market Share (%) | Growth Rate |

| North America | 35% | 4.5% |

| Asia-Pacific | 40% | 6.2% |

| Europe | 20% | 3.8% |

| Rest of World | 5% | 2.1% |

Companies are investing in new tech and strategies. They’re trying to meet the growing needs of the industry.

Cleanroom Paper Market in the U.S.: Growth Drivers and Key Insights

The U.S. cleanroom paper market is key in high-precision manufacturing. It shows a lot of growth potential. This is thanks to advanced tech in sectors like semiconductors, pharmaceuticals, and medical devices.

What’s driving the cleanroom paper market in the U.S.

- More demand in electronics making

- Higher quality control needs

- More biotech research facilities

- More investment in nanotechnology

Market insights show that special cleanroom paper is vital for ultra-clean spaces. The semiconductor industry, for example, needs these materials to avoid contamination during key steps.

| Industry Sector | Cleanroom Paper Demand | Growth Projection |

| Electronics | High | 15-20% annual growth |

| Pharmaceutical | Medium-High | 12-18% annual growth |

| Medical Devices | Medium | 10-15% annual growth |

“The cleanroom paper market in the U.S. is not just about product quality, but about ensuring precision in critical manufacturing environments.” – Industry Expert

Rules from the FDA and ISO are big drivers of growth. They set strict rules for keeping things clean, which affects what cleanroom paper is used for in many tech fields.

New tech is changing the U.S. cleanroom paper world. Makers are creating better materials to meet tougher environmental standards.

The Cleanroom Paper Market in Japan: Current Trends and Future Projections

The Japanese cleanroom paper market is at a key point. It’s where technology meets industry change. Advanced sectors like electronics, automotive, and semiconductors drive this market.

Market trends show a big chance for cleanroom paper to grow. Japan’s focus on precision makes cleanroom paper crucial for its industries.

- Electronics manufacturing represents the largest market segment

- Semiconductor industry drives specialized cleanroom paper demand

- Technological innovations enhance product performance

Looking ahead, the market is expected to grow a lot. It’s set to grow at about 5.2% each year until 2028. Japan’s market is special because of:

| Market Segment | Growth Potential | Key Drivers |

| Electronics | 6.5% | Precision Manufacturing |

| Automotive | 4.8% | Advanced Manufacturing Standards |

| Medical Devices | 5.3% | Stringent Cleanliness Requirements |

“Japan’s commitment to technological excellence continues to drive cleanroom paper market innovation.”

Japan is investing in research and development. This, along with the need for clean manufacturing, makes Japan key in the global market.

South Korea’s Role in the Global Cleanroom Paper Market

South Korea is a key player in the global cleanroom paper market. Its strong electronics and semiconductor industries drive this role. The country’s technology and market position boost growth and innovation.

The South Korea market analysis shows several strengths in cleanroom paper production:

- Advanced manufacturing capabilities

- High-precision technology development

- Strong semiconductor industry infrastructure

South Korean manufacturers play a big role in the global market, especially in high-tech sectors. Their contribution goes beyond traditional manufacturing. It includes leading-edge research and development.

| Market Segment | Contribution Percentage | Key Industries |

| Electronics | 45% | Semiconductor Manufacturing |

| Pharmaceutical | 25% | Research Laboratories |

| Medical Devices | 20% | Healthcare Technology |

| Other Industries | 10% | Specialized Manufacturing |

Korean companies have created innovative cleanroom paper solutions that meet high international standards. Their focus on technology makes them leaders in precision manufacturing materials.

The semiconductor industry, with giants like Samsung and SK Hynix, drives demand for cleanroom paper. This segment pushes technology limits and develops complex solutions for manufacturing.

Future Prospects for the Cleanroom Paper Market’s Growth and Development

The cleanroom paper market is set for big changes. Market growth prospects show strong growth ahead. New technologies and changing consumer wants are changing the industry, pushing for new ideas and strategies.

Key areas for future growth include:

- Sustainable Manufacturing: New eco-friendly ways to make products

- Nanotechnology-enhanced paper materials

- Smart contamination control solutions

- Digital integration for precise tracking

The outlook is bright for the cleanroom paper market. It will see big chances in the pharmaceutical, semiconductor, and medical device fields. New tech will lead to better cleanroom paper products.

Companies are spending a lot on research and development. They aim to meet stricter cleanliness standards. The global market will likely see more demand for top-notch cleanroom paper that meets tough industrial standards.

Innovation and adaptability will be critical drivers of success in the cleanroom paper market’s future landscape.

Asia-Pacific markets and ongoing tech improvements will be key in shaping the cleanroom paper industry. They will help ensure the market keeps growing and getting more advanced.

Competitive Forces Shaping the Cleanroom Paper Market

The cleanroom paper market is very competitive. Companies are always trying to get ahead. They look at several key factors to understand the market.

Leading manufacturers use different strategies. They invest in research, create new products, expand globally, and form partnerships.

- Integrity Cleanroom Manufacturer – United States

- Berkshire Corporation – United States

- Total Source Manufacturing – United States

- Texwipe – United States

- Shenzhen Beite Purification Technology Co., Ltd – China

- Sunbeam Creations – United States

- Connecticut Cleanroom Corporation – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Cleanroom Paper Market Report |

| Base Year | 2024 |

| Segment by Type |

· Low-Particle Paper · Synthetic Substrate Papers · Cellulose-Based Cleanroom Papers · Microfiber Cleanroom Wipes |

| Segment by Application |

· Pharmaceutical · Semiconductor Electronics · Biotechnology Research · Aerospace Engineering · Medical Device Production |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The cleanroom paper market is growing fast, with big chances in many fields. Companies should focus on new tech and expanding their reach. The forecast shows lots of chances in the semiconductor, pharmaceutical, and healthcare areas.

More people want cleanroom paper that can really keep things clean. Businesses need to work on making better products. They should also look into making products that are good for the planet.

Companies should think about making different products and using new tech. They need to make things that can change fast to meet new needs. Working with tech companies could also be a smart move.

Asia-Pacific, especially South Korea and Japan, is where the market is growing the most. Companies should make products there and work together on new tech. Being ready for changes in the market can help them grow and meet global demand.

Global Cleanroom Paper Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Cleanroom Paper Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Cleanroom Paperplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Cleanroom Paper Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Cleanroom Paper Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Cleanroom Paper Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCleanroom Paper Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is cleanroom paper and why is it important?

Cleanroom paper is a special type of paper designed for use in clean environments such as laboratories and manufacturing facilities. Its primary purpose is to maintain cleanliness and prevent the accumulation of dust and other contaminants.

Which industries primarily use cleanroom paper?

Cleanroom paper is primarily used in industries such as:

- Healthcare: Hospitals and laboratories use cleanroom paper for maintaining hygiene and preventing contamination.

- Technology: Semiconductor manufacturing and electronics companies rely on cleanroom paper to protect sensitive components during production.

- Aerospace: The aerospace industry uses cleanroom paper for manufacturing aircraft parts and ensuring cleanliness in assembly processes.

How do geopolitical factors impact the cleanroom paper market?

Geopolitical factors such as trade regulations and the global economy have a significant influence on the cleanroom paper industry. These factors can affect various aspects of the market, including:

- Manufacturing: Geopolitical tensions or trade restrictions may impact the production processes and sourcing of raw materials for cleanroom paper.

- Distribution: Changes in trade policies can affect the transportation and logistics involved in delivering cleanroom paper to different regions.

- Pricing: Fluctuations in currency exchange rates or tariffs imposed on imports/exports can directly impact the pricing structure of cleanroom paper products.

Understanding these geopolitical factors is crucial for businesses operating in the cleanroom paper market to navigate challenges and seize opportunities effectively.

What are the key challenges in the cleanroom paper market?

The cleanroom paper market faces several significant challenges, including:

- Strict regulations and compliance requirements

- High production costs and pricing pressures

- Rapid advancements in technology and the need to stay updated

- Intense competition from existing players and new entrants

- Demand for innovative solutions and product differentiation

How is the cleanroom paper market expected to grow?

The cleanroom paper market is expected to experience significant growth. This growth can be attributed to several factors:

- Increasing demand in industries such as technology and precision manufacturing

- Emerging technologies that require strict cleanliness standards

- Growing emphasis on maintaining cleanliness in various processes and environments

Which regions are leading in the development of the cleanroom paper market?

The US, Japan, and South Korea are at the forefront of cleanroom paper market development. Their advanced industries play a crucial role in driving the growth of this market.

What types of cleanroom paper products are available?

There are many types of cleanroom paper. They vary in how well they absorb and how clean they keep things.

What technological advancements are influencing cleanroom paper production?

New technology is improving cleanroom paper production. This includes:

- Advanced filtering systems

- Innovative manufacturing processes

- Environmentally friendly materials

How do sustainability concerns impact cleanroom paper development?

Companies are making eco-friendly cleanroom paper. They use green materials and make it in ways that save energy.

What factors drive innovation in the cleanroom paper market?

Innovation in the cleanroom paper market is driven by several factors including new technology, higher standards, and an increasing need for precision. This drive for innovation also stems from the necessity to address complex challenges across various fields.