Aerospace Check Valves Market to Surpass $12.3 Billion by 2025: Key Markets in the U.S., Germany, and China

Explore the expanding Aerospace Check Valves Market dynamics, driven by rising aircraft production and MRO activities. Get insights into global growth trends and emerging opportunities.

- Last Updated:

Aerospace Check Valves Market Outlook in Q1 and Q2 of 2025

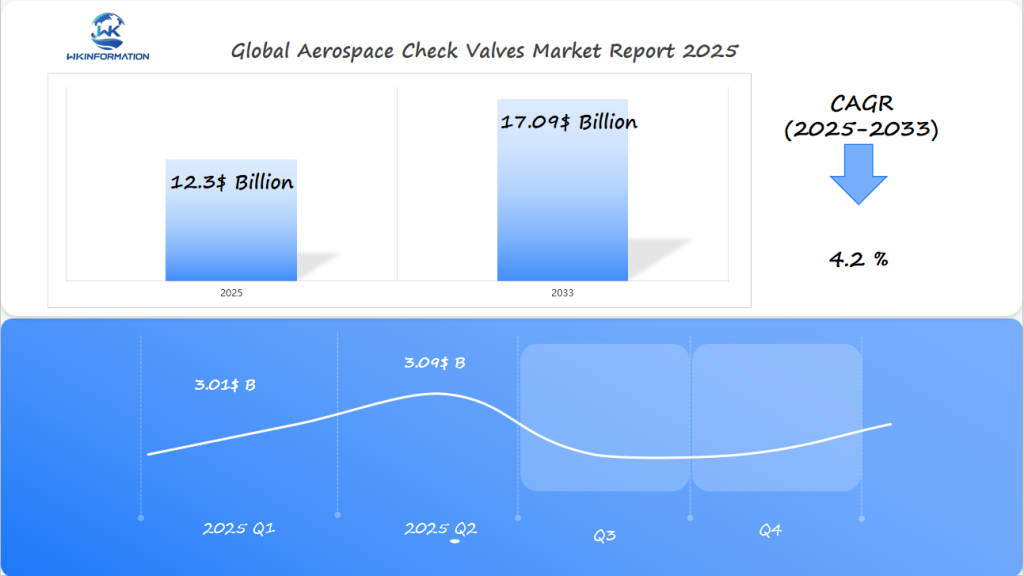

The Aerospace Check Valves market is projected to reach $12.3 billion by the end of 2025, growing at a CAGR of 4.2% from 2025 to 2033. The estimated value for Q1 2025 stands at approximately $3.01 billion, with Q2 rising to $3.09 billion, driven by rising commercial aircraft deliveries and defense aviation upgrades.

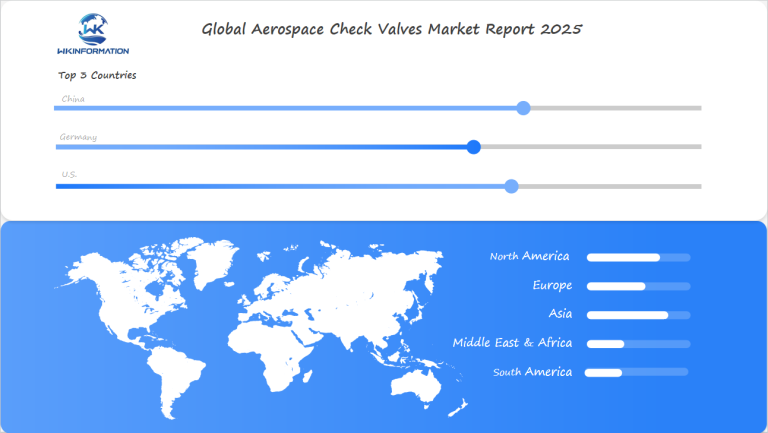

In the United States, the demand is closely tied to both civil aviation expansion and modernization of military fleets, with key OEMs and MRO players increasing check valve procurement. Germany is contributing through high-precision engineering and component exports to Airbus and other European aerospace projects. China is accelerating domestic aircraft manufacturing under programs like COMAC, further stimulating local valve production and integration.

Key Takeaways

- Aerospace check valves market expected to reach $12.3 billion by 2025

- United States, Germany, and China emerge as primary market drivers

- Commercial and military aerospace sectors show strongest growth potential

- Technological innovation remains crucial for market expansion

- Precision engineering defines competitive aerospace check valve manufacturing

Aerospace Check Valves Market Upstream and Downstream Industry Chain Analysis

The aerospace check valves industry is a complex web of processes. It turns raw materials into key parts for flying and space travel. Knowing the supply chain shows how makers, suppliers, and users are all connected.

Upstream: Raw Materials

Raw materials are the base of the aerospace check valves industry. Special makers get metals and composites for strong valve parts. These parts must be very durable and precise.

- Stainless steel alloys

- Titanium components

- High-temperature resistant ceramics

- Advanced polymer seals

Production Chain

The production chain has many important steps. Makers work with aerospace engineers to make valves for planes and spaceships. They make sure the valves fit exactly what’s needed.

| Production Stage | Key Activities | Critical Considerations |

| Raw Material Sourcing | Material selection and procurement | Quality, performance, cost-effectiveness |

| Component Manufacturing | Precision machining and fabrication | Tolerance, durability, weight optimization |

| Quality Control | Rigorous testing and certification | Safety, reliability, compliance |

Downstream: Aerospace Systems

Downstream, check valves are put into big aerospace systems. Plane makers and space teams need these parts for control. They make sure everything works right, even in tough conditions.

The Need for Collaboration

The aerospace check valves supply chain needs new ideas and teamwork. Material scientists, engineers, and makers must work together. They do this to keep up with new tech needs.

Market Trends Driving the Aerospace Check Valves Industry in 2025

The aerospace check valves industry is changing fast. New technologies and market changes are leading the way. These changes are making manufacturers rethink how they design and make valves in 2025.

Several key trends are shaping the future of aerospace check valves:

- Enhanced fuel efficiency technologies

- Lightweight material innovations

- Smart valve integration with digital systems

- Increased demand for precision engineering

Enhanced Fuel Efficiency Technologies

New technologies are changing how valves are made. Aerospace engineers are using advanced materials like carbon composites and high-performance polymers. These materials help make planes lighter without losing performance.

There’s also a big push for valves that are better for the environment. Companies are working on designs that use less energy and control fluids better. Precision engineering is becoming more important in the aerospace market.

Lightweight Material Innovations

There’s a big move towards smart check valves that can send real-time data. These advanced valves help with maintenance, reducing failures and making planes more reliable.

Smart Valve Integration with Digital Systems

The integration of nanotechnology into valve design is expected to enhance their functionality and performance further.

Predictive maintenance capabilities will be incorporated into check valves, allowing for proactive monitoring and servicing.

Enhanced durability under extreme conditions will be achieved through innovative manufacturing processes and material selection.

Challenges and Limitations in Aerospace Check Valve Production

The aerospace check valve production world is full of complex challenges. Manufacturers must be very precise and skilled to overcome these hurdles. Ensuring safety and reliability is a top priority.

Quality Control

Quality control is key for aerospace check valve makers. The aviation and space sectors have very high standards. To meet these, manufacturers use many inspections and tests.

- Advanced material selection for extreme environments

- Precision machining tolerances within microns

- Comprehensive testing protocols

- Continuous monitoring of production processes

Regulatory Compliance

Following regulations is another big challenge. Manufacturers must follow rules from the FAA, NASA, and EASA. These rules cover design, making, and documentation.

Scaling Up Production

Scaling up production without losing quality is tough. To solve this, makers use automated tech and partnerships. They also use advanced models to predict how valves will perform under stress.

The industry keeps finding new ways to solve old problems. They use advanced engineering and work together on research projects.

Geopolitical Impact on Aerospace Check Valves Trade and Manufacturing

The world of aerospace check valves trade is getting more complex. This is because of the complex politics between countries. Rules and policies are changing how these parts are made and sold.

Important things affecting the aerospace check valves market include:

- Shifting trade tensions between major economic powers

- Emerging protectionist tariffs in aerospace manufacturing

- Strategic realignment of global supply chains

Companies are finding new ways to deal with these issues. Diversifying production locations is a key strategy. It helps avoid problems caused by trade limits.

Places like the United States, China, and Europe are leading in changing how aerospace parts are made. Tariffs and rules are making companies do things like:

- Set up local factories

- Make strategic partnerships

- Invest in new technologies

These changes are making a big impact on the aerospace check valves market worldwide. Companies need to be quick and flexible to stay ahead in this fast-changing world.

Type Segmentation: High-Pressure vs. Low-Pressure Aerospace Check Valves

Aerospace check valves are key in aviation systems. Their pressure ratings show how they work. They are made for different needs in aircraft.

High-pressure and low-pressure valves have big differences in design:

- High-pressure valves deal with tough conditions

- Low-pressure valves help with aircraft systems

- Special valves are made for specific tasks

Choosing the right check valve is crucial. Engineers look at material, strength, and how well they work.

| Valve Type | Pressure Range | Primary Applications |

| High-Pressure Check Valves | 1000-5000 PSI | Hydraulic Systems, Fuel Delivery |

| Low-Pressure Check Valves | 50-500 PSI | Pneumatic Controls, Cooling Systems |

New trends are mixing old pressure types. This is thanks to new materials and better making techniques. Aerospace makers keep improving valve designs for better systems.

Applications for Aerospace Check Valves in Aviation and Space Exploration

Aerospace check valves are key in aviation and space exploration. They ensure fluids flow in one direction and stop backflow. This is vital for keeping systems running smoothly.

Roles of Check Valves in Aviation

In aviation, check valves have many important roles:

- Managing fuel

- Controlling hydraulic pressure

- Maintaining a stable environment

- Supporting engine pneumatic systems

Importance of Check Valves in Space Exploration

Space exploration needs advanced check valve technology. Rocket propulsion systems use these valves for precise control in harsh conditions. Satellites also rely on them for fluid management in space.

| System Type | Check Valve Application | Key Performance Requirements |

| Aircraft Fuel Systems | Preventing fuel backflow | High reliability, low pressure drop |

| Rocket Propulsion | Regulating propellant flow | Extreme temperature resistance |

| Life Support Systems | Controlling gas and liquid circulation | Precision and fail-safe operation |

Innovation in aerospace check valves is ongoing. New materials and methods are making valves smaller, lighter, and more reliable. This meets the growing needs of aviation and space exploration.

Global Market Analysis: Regional Insights into Aerospace Check Valves Demand

The global aerospace check valves market is growing fast in many places. The demand for these valves varies a lot, with new aerospace centers leading the way in different areas.

Each key region has its own special traits in using aerospace check valves:

- Asia-Pacific is growing fast with more airports and airfields.

- Middle Eastern markets are getting bigger with more aerospace factories.

- Latin American areas are building special aerospace supply chains.

Looking ahead, the market sees big chances because of:

- Government spending on new aviation tech.

- More planes being made for both business and military use.

- New tech in making valves.

Looking at demand, we see important trends in the aerospace check valves world. Emerging markets like India, Brazil, and Singapore are really promising for growth.

Companies are working hard to fit into these regional markets. They’re changing how they make things to meet the needs of each area’s aerospace industry.

U.S. Market Analysis: Advanced Aerospace Technologies and Check Valve Applications

The U.S. aerospace industry is at the forefront of technology, making significant progress in the use of check valves. Leading companies such as Boeing, Lockheed Martin, and Northrop Grumman are actively involved in developing advanced valve systems for critical aerospace operations.

Technological Advancements in Aerospace Check Valves

New technologies are reshaping the landscape of aerospace check valves. Manufacturers are now utilizing high-quality materials and precise engineering techniques to create innovative valve designs. This shift is evident in the rapid growth of the aerospace valves market, which reflects the increasing demand for superior components.

Key Factors Driving Growth in Aerospace Check Valve Technology

- Material Advancements: The introduction of titanium-based valve designs offers exceptional strength-to-weight ratios, making them ideal for aerospace applications.

- Manufacturing Precision: The implementation of precision machining techniques enhances valve reliability, ensuring optimal performance even in challenging conditions.

- Composite Innovations: The use of advanced composite materials further improves valve performance, particularly in extreme environments.

Government Initiatives and Their Impact on Innovation

Government initiatives, particularly those spearheaded by NASA and defense contracts, play a crucial role in fostering innovation within the field of aerospace check valves. These efforts prioritize the development of more efficient, lightweight, and robust valve systems capable of addressing complex aerospace challenges.

| Key U.S. Aerospace Check Valve Manufacturers | Specialization | Primary Applications |

| Parker Hannifin | High-pressure valve systems | Commercial and military aircraft |

| Honeywell International | Advanced materials engineering | Aerospace propulsion systems |

| Woodward, Inc. | Precision control technologies | Aerospace and defense applications |

The U.S. aerospace industry demonstrates remarkable resilience and ingenuity. It stands as a global frontrunner in the development of cutting-edge check valve technologies tailored to meet stringent aerospace requirements.

Germany's Aerospace Sector: Leadership in Aerospace Check Valve Production

Germany leads in European aerospace innovation, especially in making check valves. The country’s engineering skills have made it famous for top-notch aerospace parts. German makers use their aerospace valves market know-how to create advanced solutions.

Germany’s aerospace check valve production has several strong points:

- Advanced Industry 4.0 manufacturing techniques

- Exceptional precision engineering capabilities

- Stringent quality control processes

- Innovative research and development investments

European aerospace makers see Germany as key in valve tech. The country’s focus on precision ensures top performance and reliability in aerospace. German engineering is known for excellence, leading to big steps in valve design and making.

German valve makers team up with big aircraft companies. This partnership uses the latest tech and high standards. Germany keeps leading in aerospace check valve making worldwide.

China's Role in Aerospace Check Valve Manufacturing and Export

China has become a major player in manufacturing aerospace check valves for the global market. Its rapid growth has positioned it as a strong competitor in the aerospace technology industry.

Factors Contributing to China’s Leadership in Aerospace Check Valves

China’s strategic moves in manufacturing have propelled it to the forefront of aerospace check valve production:

- Significant investments in research and development

- Access to advanced technology

- Competitive pricing

- Increasing number of domestic aerospace projects

The Growing Market for Chinese Aerospace Check Valves

The demand for Chinese-made aerospace check valves is expanding rapidly. These valves are designed to meet international quality standards through:

- Rigorous quality control measures

- Collaborations with global companies

- Adoption of cutting-edge technologies

| Manufacturing Aspect | Chinese Performance | Global Ranking |

| Production Capacity | High | Top 3 |

| Export Volume | Growing | Emerging Leader |

| Technological Innovation | Advancing Rapidly | Competitive |

Chinese manufacturers are focusing on specific components used in aerospace check valves. Their goal is to achieve high quality while keeping costs low. This approach makes them appealing to aerospace companies worldwide.

Future Development: Innovations and Market Trends for Aerospace Check Valves

The aerospace check valves market is changing fast. New technologies are making aircraft systems better. Valve design, materials, and how they work are all getting a boost.

Some big changes coming include:

- Advanced 3D printing for complex shapes

- Smart sensors for early maintenance alerts

- Lightweight, strong composite materials

- Real-time monitoring for better performance

Now, the focus is on being green and efficient. Aerospace companies are looking for new check valves. They want ones that are lighter, more reliable, and better for the planet. Materials like carbon-fiber composites and ceramic-based alloys are key in these advancements.

As planes become more electric, there’s a big chance for new valve designs. Companies are working hard to make valves that can handle tough conditions. They aim to keep performance high.

New trends show big chances for aerospace check valves in:

- Electric propulsion systems

- Autonomous aerial vehicles

- Space exploration missions

- Sustainable aviation technologies

These changes are changing aerospace engineering. They promise more efficient, reliable, and eco-friendly check valves for the industry.

Competitive Landscape: Key Players and Market Strategies in Aerospace Check Valves

The aerospace check valves market is full of competition. It’s driven by new ideas and partnerships. Big names like Parker Hannifin, Eaton Corporation, and Honeywell International lead the way. They invest in cutting-edge tech and have a strong global presence.

Key Players:

- Emerson Electric — USA

- ZFA Valve — China

- Flowserve Corporation — USA

- Crane Fluid Systems — United Kingdom

- Weir Group — United Kingdom

- Curtiss-Wright Corporation — USA

- Honeywell International — USA

- Bosch Rexroth AG — Germany

- Parker Hannifin — USA

- Eaton Corporation — Ireland

Looking at the competition, we see a few main strategies:

- Extensive research and development programs

- Strategic partnerships with aerospace manufacturers

- Advanced manufacturing technologies

- Customized valve solutions for specialized applications

Smaller companies are finding their place by making precise valves for aerospace. They use advanced engineering to keep up with the big guys.

| Company | Market Strategy | Key Strength |

| Parker Hannifin | Global expansion | Comprehensive product portfolio |

| Eaton Corporation | Technology innovation | High-pressure valve systems |

| Honeywell International | Aerospace system integration | Advanced control technologies |

New players from China and India are shaking things up. They’re getting better at making valves and reaching more markets worldwide.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Aerospace Check Valves Market Report |

| Base Year | 2024 |

| Segment by Type |

· High-pressure valves · Low-pressure valves |

| Segment by Application |

· Aviation · Space Exploration · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The aerospace check valves market is growing fast, expected to hit $12.3 billion by 2025. The U.S., Germany, and China are leading the way with new tech and market chances.

More aerospace parts are being made, and new techs are coming out. Companies are making high-quality check valves for planes and space. They’re using advanced materials and designs to make valves better and more efficient.

There’s a lot of potential in aerospace tech around the world. The U.S. is leading in new tech, Germany in engineering, and China in making things. This mix of skills is making the market grow.

But, there are challenges too. Making these parts is hard, rules keep changing, and there’s a lot of competition. To succeed, companies need to keep innovating, focus on quality, and stay up-to-date with trends.

The future of the market depends on how well companies use new tech and make smart investments. It’s all about staying ahead in the game of aerospace check valves.

Global Aerospace Check Valves Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Aerospace Check Valves Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Aerospace Check Valves Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Aerospace Check Valves Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Aerospace Check Valves Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Aerospace Check Valves Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Aerospace Check Valves Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Aerospace Check Valves Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for aerospace check valves by 2025?

The aerospace check valves market is expected to hit $12.3 billion by 2025. This growth is due to more aircraft being made and maintained.

Which key markets are driving the aerospace check valves industry?

The U.S., Germany, and China are leading the way. Each brings its own strengths in aerospace tech and manufacturing.

What are the main challenges in aerospace check valve production?

Making aerospace check valves is tough. It requires strict quality checks, following complex rules, picking the right materials, and precise manufacturing.

How do geopolitical factors impact aerospace check valve trade?

Trade policies, tariffs, and tensions between big countries like the U.S. and China affect the aerospace check valve market a lot.

What are the key applications of aerospace check valves?

Aerospace check valves are vital in many areas:

- Fuel systems

- Hydraulic systems

- Environmental control systems

- Rocket propulsion

- Satellite fluid management

- Life support for space missions

What technological innovations are emerging in aerospace check valve design?

New technologies such as 3D printing for valve production, smart sensors for maintenance, and advanced materials are reshaping the manufacturing process of valves.

How are different regions approaching aerospace check valve manufacturing?

The U.S., Germany, and China are each taking their own path. The U.S. focuses on new tech, Germany on precision, and China on growing its manufacturing.

What drives the demand for aerospace check valves?

The demand for aerospace check valves is increasing due to several factors:

- More people are traveling by air.

- Low-cost airlines are growing in number.

- There is a greater emphasis on fuel efficiency and environmentally-friendly practices.

- New technologies in the aerospace industry are also contributing to the demand.

How are check valves classified in the aerospace industry?

Check valves are split into high and low-pressure types. Each is made for different uses in aircraft and space systems.

What role do check valves play in space exploration?

Check valves are essential for rocket systems, managing fluids in satellites, and life support in space. They need to be very precise and reliable.