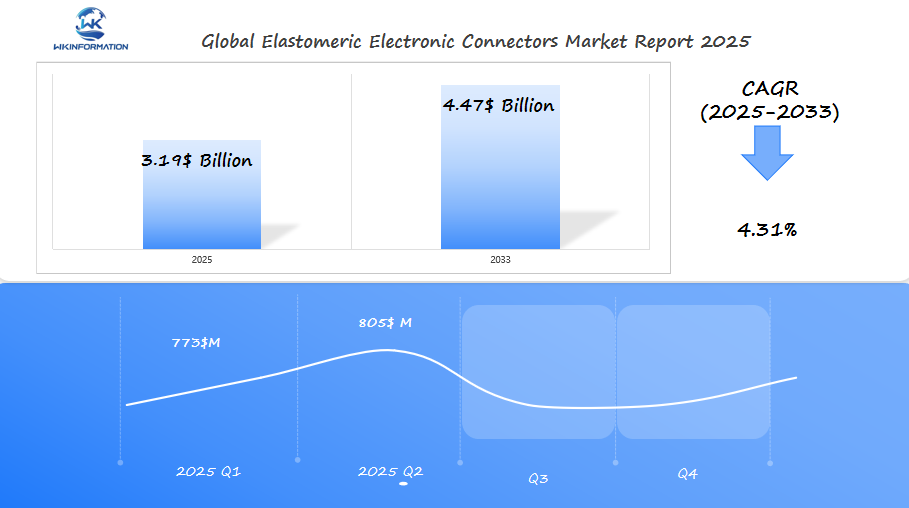

$3.19 Billion Elastomeric Electronic Connectors Market Set for Growth in Japan, the U.S., and Germany by 2025

The market size will reach USD 3.19 billion in 2025 and is expected to reach USD 4.47 billion by 2033, with a CAGR of 4.31% from 2025 to 2033.

- Last Updated:

Projected Market Insights for Elastomeric Electronic Connectors in Q1 and Q2 of 2025

The Elastomeric Electronic Connectors market is expected to reach $3.19 billion in 2025, with a CAGR of 4.31% from 2025 to 2033. In Q1, the market is projected to generate around $773 million, driven by demand across industries like automotive, consumer electronics, and industrial equipment.

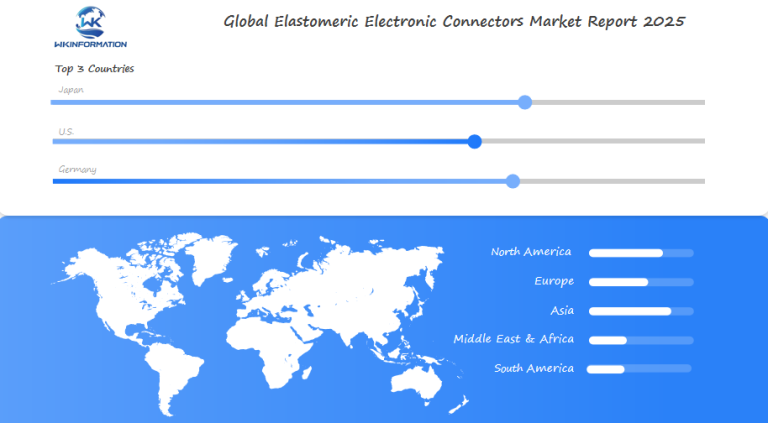

By Q2, the market is expected to grow to approximately $805 million, reflecting steady growth as industries continue to adopt advanced connectors for their versatility and durability in high-performance environments. Japan, the U.S., and Germany are expected to be the leading markets, with Japan’s strong automotive and electronics sectors driving demand, the U.S. leveraging its extensive electronics manufacturing base, and Germany’s industrial sector further increasing connector demand.

The continuous push for smaller, more efficient electronic components will contribute to the market’s growth in these regions, as elastomeric connectors offer a reliable solution for various challenging environments.

Understanding the Industry Chains for Elastomeric Electronic Connectors

The elastomeric electronic connectors industry relies on a complex system of suppliers, manufacturers, and end-users. To better understand this industry, let’s explore both the upstream and downstream supply chains.

Upstream Supply Chain

The upstream supply chain includes raw material providers who specialize in:

- Base elastomer materials: such as silicone rubber and thermoplastic elastomers

- Conductive fillers: including carbon black and metal particles

- Chemical additives: like curing agents and stabilizers

Key players in this upstream sector, such as BASF SE and DuPont de Nemours Inc., play a crucial role by supplying these essential materials to connector manufacturers. It is imperative for these suppliers to implement rigorous quality control measures in order to guarantee consistency and performance of their materials.

Downstream Supply Chain

On the other hand, the downstream supply chain reveals various demand patterns across multiple sectors:

- Primary manufacturers: who transform raw materials into specialized elastomeric compounds

- Component fabricators: responsible for creating the finished connectors

- System integrators: incorporating connectors into final products

Demand trends indicate an increasing need for:

- High-performance materials specifically designed for automotive applications

- Flexible connectors suitable for portable electronics

- Reliable components intended for medical devices

The manufacturing processes involved in both upstream and downstream operations require precise coordination in order to maintain product quality. Manufacturers face the challenge of balancing material costs, production efficiency, and market demands while also adhering to industry standards and specifications.

Recent disruptions in the supply chain have emphasized the importance of having strong supplier networks and alternative sourcing strategies in place. This is crucial for ensuring uninterrupted production capabilities within the industry.

Key Market Trends Shaping the Elastomeric Electronic Connector Industry

Recent technological breakthroughs have transformed elastomer manufacturing, introducing advanced materials with enhanced properties:

- Nano-engineered Elastomers: New compounds featuring improved conductivity and durability

- Smart Materials: Self-healing elastomers that can repair minor damage automatically

- Temperature-resistant Variants: Materials capable of withstanding extreme conditions from -40°C to 150°C

Demand from the Electric Vehicle Sector

The electric vehicle (EV) sector drives significant demand for elastomeric connectors. These components play critical roles in:

- Battery management systems

- Power distribution units

- Charging interfaces

- Safety monitoring systems

Innovations in Eco-friendly Manufacturing

Sustainability initiatives have sparked innovations in eco-friendly manufacturing:

- Bio-based Elastomers: Derived from renewable resources, reducing carbon footprint

- Recyclable Components: Design modifications enabling easier end-of-life material recovery

- Energy-efficient Production: Advanced manufacturing processes consuming less energy

Market leaders have adopted green manufacturing practices while maintaining high performance standards. Companies like BASF SE integrate recycled materials into their production lines without compromising connector reliability.

The Shift Toward Lightweight Materials

The shift toward lightweight materials continues to accelerate, with manufacturers developing new compounds that reduce component weight by up to 30% compared to traditional materials. These advancements particularly benefit portable electronics and automotive applications where weight reduction directly impacts energy efficiency.

Challenges in the Production of Elastomeric Electronic Connectors

Manufacturing elastomeric electronic connectors presents several critical challenges that impact production efficiency and product quality. These challenges include:

- Raw material sourcing issues

- Quality control demands

- Integration of sustainable practices

- Quality assurance testing requirements

Let’s take a closer look at each of these challenges.

Raw Material Sourcing Issues

Raw material sourcing stands as a primary concern for manufacturers, with several factors affecting their ability to obtain the materials needed for production:

- Limited availability of high-grade silicone compounds

- Price volatility in raw materials

- Supply chain disruptions affecting material procurement

- Stringent regulatory requirements for material certification

Quality Control Demands

Quality control is crucial in ensuring that elastomeric electronic connectors meet the required standards. This involves implementing sophisticated testing protocols throughout the production process to maintain:

Temperature Control Requirements

- Precise temperature regulation during molding

- Consistent curing conditions

- Thermal stability monitoring

Material Consistency Challenges

- Uniform dispersion of conductive particles

- Prevention of air bubble formation

- Consistent electrical conductivity across batches

Integration of Sustainable Practices

As sustainability becomes increasingly important, manufacturers are faced with the challenge of integrating eco-friendly practices into their production processes. This includes:

- Reducing waste during production

- Implementing energy-efficient manufacturing methods

- Developing recyclable material alternatives

- Meeting environmental compliance standards

Quality Assurance Testing Requirements

To ensure that elastomeric electronic connectors meet specific performance criteria, manufacturers must conduct thorough quality assurance testing. This requires specialized equipment and expertise to verify:

- Electrical conductivity parameters

- Mechanical strength specifications

- Environmental resistance capabilities

- Dimensional accuracy tolerances

These production challenges directly influence manufacturing costs and production timelines, pushing manufacturers to innovate their processes while maintaining strict quality standards.

Geopolitical Factors Affecting Elastomeric Electronic Connectors Market Growth

Trade tensions between major economies create significant ripple effects across the elastomeric electronic connectors supply chain. The U.S.-China trade relationship impacts raw material costs and manufacturing decisions, pushing companies to diversify their production locations.

Key Regional Impacts:

- Japan: Strategic partnerships with Southeast Asian nations help maintain stable supply chains

- United States: Reshoring initiatives drive domestic production capacity expansion

- Germany: EU regulatory frameworks shape production standards and trade relationships

Recent global semiconductor shortages highlight the vulnerability of cross-border supply chains. Companies now implement multi-sourcing strategies and establish regional manufacturing hubs to mitigate risks.

Trade Policy Implications:

- Tariff fluctuations affect component pricing

- Import/export regulations influence production locations

- Regional content requirements shape sourcing decisions

The establishment of new trade agreements creates opportunities for market expansion. The RCEP (Regional Comprehensive Economic Partnership) opens new channels for Asian manufacturers, while the USMCA strengthens North American trade relationships.

Local content requirements push manufacturers to establish production facilities in key markets. This trend benefits domestic suppliers and creates new opportunities for technology transfer between regions.

Rising geopolitical tensions in strategic regions prompt manufacturers to develop contingency plans and alternative supply routes. Companies invest in inventory management systems and local partnerships to ensure consistent product availability.

Market Segmentation: Types and Applications of Elastomeric Electronic Connectors

The elastomeric electronic connectors market features distinct categories based on design specifications and application requirements.

Primary Connector Types

- Vertical Elastomeric Connectors: Designed for perpendicular circuit board connections

- Horizontal Elastomeric Connectors: Specialized for parallel board-to-board connections

- Matrix Array Connectors: Used in high-density applications requiring multiple contact points

- Zero Insertion Force (ZIF) Connectors: Built for applications requiring frequent connect/disconnect cycles

Key Application Sectors

Automotive Electronics

- Dashboard displays

- Engine control units

- Infotainment systems

- Battery management systems

Consumer Electronics

- Smartphones

- Tablets

- LCD displays

- Gaming consoles

Industrial Equipment

- Control panels

- Testing equipment

- Monitoring systems

- Automation devices

Medical Devices

- Patient monitoring equipment

- Diagnostic tools

- Surgical instruments

- Imaging systems

The market segmentation reflects specific industry requirements, with each connector type engineered to meet precise performance standards. Custom designs address unique application needs, supporting the diverse range of electronic devices across different sectors.

Elastomeric Electronic Connectors in Automotive and Consumer Electronics

The automotive industry’s rapid evolution drives significant demand for elastomeric electronic connectors. These components play a vital role in electric vehicles (EVs), serving as essential interfaces in:

- Battery management systems

- Power distribution units

- Motor control modules

- Advanced driver assistance systems (ADAS)

Traditional vehicles utilize elastomeric connectors in multiple applications, including:

- Dashboard displays

- Infotainment systems

- Climate control interfaces

- Engine management systems

In the consumer electronics sector, elastomeric connectors demonstrate exceptional versatility. Manufacturers integrate these components into:

- Smartphones – linking display panels to main circuit boards

- Tablets – connecting touch-sensitive components

- Laptops – joining keyboard assemblies

- Gaming consoles – securing internal display connections

The unique properties of elastomeric connectors make them ideal for these applications:

- Space Efficiency: Compact design allows for slimmer device profiles

- Shock Absorption: Natural dampening properties protect sensitive components

- Temperature Resistance: Stable performance across varying thermal conditions

- Cost-Effectiveness: Reduced assembly time and maintenance requirements

Recent innovations in elastomeric materials have enhanced connector durability and conductivity, meeting the increasing demands of modern electronic devices. These advancements support higher data transmission rates and improved signal integrity, critical for both automotive and consumer electronics applications.

Global Market Overview of Elastomeric Electronic Connectors

The global market for elastomeric electronic connectors shows clear patterns of growth in different regions. North America holds a significant portion of the market, primarily due to:

- Well-developed manufacturing infrastructure

- High usage rates in medical devices

- Strong presence of major industry companies

- Significant investments in research and development

On the other hand, Asia-Pacific is the region experiencing the fastest growth, thanks to:

- China: The leading manufacturing center for electronic parts

- South Korea: Advanced technology capabilities in consumer electronics

- Taiwan: Specialized knowledge in semiconductor production

Key Characteristics of the Market

The market exhibits the following important features:

- Market Concentration: The top five manufacturers control 45% of global production.

- Regional Distribution:

- North America holds a 35% market share.

- Asia-Pacific accounts for 40% of the market.

- Europe has a 20% market share.

- The rest of the world makes up 5% of the market.

Current estimates suggest that the market will grow at a compound annual growth rate (CAGR) of 6.8% until 2025. Fluctuations in raw material prices have an impact on manufacturing costs in different regions, but Asian markets still have an advantage due to lower production expenses.

Distribution Channels

The distribution network for elastomeric electronic connectors includes various channels:

- Direct sales to original equipment manufacturers (OEMs)

- Authorized distributors

- Online business-to-business (B2B) platforms

- Regional supply partnerships

These factors create opportunities for both established companies and new entrants, especially in developing economies where infrastructure development drives the demand for electronic components.

Japan's Role in the Growth of Elastomeric Electronic Connectors Market

Japan’s technological expertise makes it a major player in the elastomeric electronic connectors market. The country’s manufacturing industry is known for its exceptional skills in precision engineering, especially when it comes to making things smaller and ensuring top-notch quality control.

Key Manufacturing Strengths:

- Advanced automation systems for high-precision production

- Strict quality control protocols

- Specialized clean room facilities

- Strong research and development infrastructure

Japanese manufacturers have created their own technologies for making elastomeric connectors, with a focus on:

- Using materials that conduct electricity better

- Making products more durable in extreme conditions

- Minimizing harm to the environment

- Developing advanced silicone compounds

The local market benefits from strong collaborations between suppliers of materials and manufacturers of electronics. Companies such as Shin-Etsu Chemical and Sumitomo Electric Industries are at the forefront of innovation in elastomeric materials and manufacturing techniques.

Local Industry Developments:

- Incorporating IoT solutions into production lines

- Using AI-driven systems for quality control

- Creating customized solutions for specific industries

- Setting up specialized training programs for skilled workers

Japan’s dedication to producing high-quality products attracts partnerships with international companies, especially in the automotive and consumer electronics sectors. The country’s expertise in precision engineering opens up unique opportunities for specialized applications of elastomeric connectors, leading to growth in the market both domestically and globally.

U.S. Market Demand for Elastomeric Electronic Connectors

The U.S. market for elastomeric electronic connectors is experiencing strong growth due to several important factors. The defense and aerospace industries are major drivers of this demand, as military applications require connectors that can perform exceptionally well in extreme conditions.

Key Factors Driving Market Growth:

- Rapid expansion of 5G infrastructure deployment

- Growing medical device manufacturing sector

- Increased adoption of IoT devices

- Rising demand in aerospace and defense applications

One area that stands out as a significant contributor to this growth is the medical technology sector. Manufacturers in the U.S. are using elastomeric connectors in various portable medical devices, patient monitoring systems, and diagnostic equipment. These applications have specific requirements for reliable and moisture-resistant connections, which is exactly what elastomeric solutions offer.

The tech ecosystem in Silicon Valley also plays a crucial role in driving innovation when it comes to connector design. Companies in this region are actively developing specialized elastomeric solutions tailored for:

- Wearable technology

- Smart home devices

- Data center equipment

- Industrial automation systems

U.S. manufacturers are placing a strong emphasis on creating custom elastomeric connector solutions that cater to the specific needs of different industries. This trend towards miniaturization is particularly evident in consumer electronics and portable devices, where there is a growing demand for micro-scale connectors.

In addition, research institutions across the country are making significant contributions to advancements in material science. They are working on developing enhanced elastomer compounds that offer improved conductivity and durability properties. These innovations position the U.S. market as a leading hub for next-generation connector technologies.

Germany's Technological Advancements in Elastomeric Electronic Connectors

German engineering excellence drives significant innovations in elastomeric connector technology. The country’s manufacturing sector has established new benchmarks through:

- Advanced Material Development

- Creation of high-performance silicone compounds

- Integration of nano-materials for enhanced conductivity

- Development of self-healing elastomeric materials

- Precision Manufacturing

- Implementation of Industry 4.0 practices

- Automated quality control systems

- High-precision molding techniques

German manufacturers like Infineon Technologies and HARTING Technology Group have pioneered breakthrough technologies in elastomeric connectors. Their research facilities focus on:

“Creating next-generation connectors that combine durability with unprecedented conductivity levels” – German Engineering Association

The innovation landscape in Germany benefits from:

- Strong collaboration between universities and industry

- Substantial R&D investments

- Robust intellectual property protection

German manufacturers lead in developing:

- Ultra-thin elastomeric connectors for miniaturized devices

- Temperature-resistant compounds for extreme conditions

- Smart connectors with integrated sensing capabilities

- Eco-friendly manufacturing processes

These advancements position German manufacturers at the forefront of elastomeric connector innovation, particularly in automotive and industrial applications.

Future Opportunities in the Elastomeric Electronic Connectors Market

The elastomeric electronic connectors sector presents significant growth potential across several emerging markets and applications. The Asia-Pacific region stands out as a prime growth territory, with countries like India, Vietnam, and Thailand showing increased demand for consumer electronics and automotive components.

Key Growth Areas:

- Smart wearable devices market expansion

- Integration with Internet of Things (IoT) devices

- Medical device miniaturization

- Renewable energy applications

The medical technology sector offers substantial opportunities, particularly in portable diagnostic devices and implantable medical equipment. You’ll find elastomeric connectors becoming essential in developing smaller, more efficient medical devices that require reliable electrical connections in compact spaces.

The renewable energy sector presents another promising avenue. Solar panel manufacturers are exploring elastomeric connectors for their durability and weather resistance properties. Wind turbine systems also benefit from these connectors’ ability to withstand extreme conditions.

Emerging Applications:

- 5G infrastructure development

- Aerospace components

- Smart city technologies

- Advanced manufacturing systems

The rise of smart manufacturing creates additional opportunities. Industry 4.0 initiatives require robust, flexible connection solutions for automated systems and robotics. These applications demand connectors capable of handling high-speed data transmission while maintaining signal integrity under demanding industrial conditions.

Competitive Landscape in the Elastomeric Electronic Connectors Industry

- Fujipoly – Nakahara-ku, Kawasaki, Kanagawa, Japan

- TE Connectivity – Schaffhausen, Switzerland

- Shin-Etsu Chemical Co., Ltd. – Chiyoda-ku, Tokyo, Japan

- Sekisui Chemical Co., Ltd. – Osaka, Japan

- Glory Sun Group – Hong Kong

- Z-Axis Connector Company – St. Petersburg, Florida, USA

- CAD (HK) – Hong Kong

- You Eal

- Ruter Elastomer

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Elastomeric Electronic Connectors Market Report |

| Base Year | 2024 |

| Segment by Type |

·Carbon |

| Segment by Application |

·LCD and Electroluminescent Displays |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The elastomeric electronic connectors market demonstrates remarkable potential, driven by evolving market dynamics and technological advancements. A detailed analysis of trends reveals significant market opportunities across diverse applications, including consumer electronics, automotive, and medical devices. The segmentation insights highlight the growing demand for compact, durable, and sustainable solutions. Competitive market dynamics showcase innovation and strategic collaborations as key growth drivers.

The market outlook emphasizes robust growth rates, with industries leveraging these connectors to meet modern demands. As innovation and sustainability continue to shape the landscape, stakeholders can capitalize on future market opportunities to achieve long-term success.

Global Elastomeric Electronic Connectors Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Elastomeric Electronic Connectors Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Elastomeric Electronic ConnectorsMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Elastomeric Electronic Connectorsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Elastomeric Electronic Connectors Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Elastomeric Electronic Connectors Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Elastomeric Electronic Connectors Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofElastomeric Electronic Connectors Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the key factors influencing the upstream supply chain for elastomeric electronic connectors?

The upstream supply chain for elastomeric electronic connectors is influenced by several key factors including material sourcing, manufacturing capabilities, and relationships with suppliers. Understanding these dynamics helps in identifying the main players involved and their impact on production efficiency.

How are technological advancements shaping the elastomeric electronic connector industry?

Recent technological advancements in elastomers have significantly improved connector technology, leading to enhanced performance and durability. Innovations such as lightweight materials and eco-friendly manufacturing processes are driving growth, particularly in sectors like electric vehicles.

What challenges does the elastomeric electronic connectors market face during production?

The production of elastomeric electronic connectors faces challenges related to material sourcing, sustainability practices, and maintaining quality control. Ensuring reliable performance while meeting eco-friendly standards is crucial for manufacturers in this competitive market.

How do geopolitical factors affect the growth of the elastomeric electronic connectors market?

Geopolitical factors such as trade policies and regional stability play a significant role in shaping market growth for elastomeric electronic connectors. Key regions like Japan, the U.S., and Germany are particularly affected by these influences, impacting production and distribution strategies.

What types of applications utilize elastomeric electronic connectors?

Elastomeric electronic connectors are utilized across various application sectors, primarily in automotive industries including electric vehicles (EVs) and traditional vehicles. They also play a vital role in consumer electronics, where reliability and performance are essential.

What future opportunities exist within the elastomeric electronic connectors market?

Future opportunities in the elastomeric electronic connectors market include expanding into emerging markets with high growth potential and leveraging technological innovations to enhance product offerings. Stakeholders should focus on evolving trends to capitalize on these opportunities.